Your space, Our solution.

Modular Timber Buildings

Discover the freedom

of space utilization.

Step into a world where nature meets modern design and technology.

I am interestedThe First Wooden Module in Europe

Our modules represent a revolutionary solution for all types of clients. We are the first pioneers in Europe to introduce a unique product that moves traditional steel containers to the low-cost sidelines. Instead, we offer a modular construction made of wood with minimal metal reinforcement.

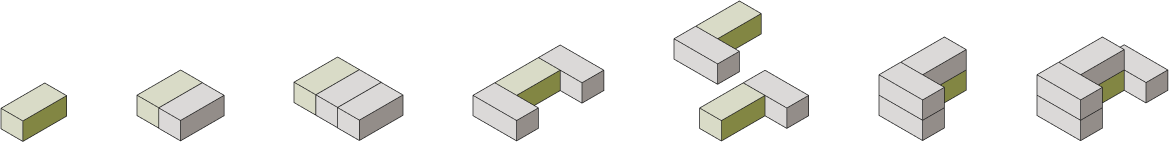

We can create various modular variations tailored to your project.

Why Choose Our Wooden

Module or Assembly?

Our modules come with nothing but advantages.

Completion of the entire modular assembly in ONE DAY

Regardless of the size of the project, we guarantee that we will deliver and assemble the entire modular system in one day. Thanks to the well-thought-out design and easy assembly, your space can be completed in record time, saving not only costs but, above all, time.

Price

The price of our modules is influenced by the choice of materials and configuration. The selection of individual components and equipment is up to you, based on what best meets your requirements, budget, and needs. Our modules are more cost-effective than traditional brick buildings, saving you not only costs but also time.

More usable space and minimal operating costs

Thanks to our ModuleWorks solution, the operating costs of your space will be minimal. We use PUR foam within the wooden structure, serving as thermal insulation. The foam is injected under high pressure into the wooden framework, where it subsequently expands. The properties of PUR foam surpass standard materials due to its excellent insulation parameters and minimal thickness. Its thermal conductivity coefficient is up to 40% better than that of other insulation materials, resulting in approximately 10% more usable space.

Sustainability

We love working with customers who prioritize protecting and preserving the diversity and integrity of natural ecosystems, such as water, soil, and climate. Our modules are primarily made of wood, a material we deeply appreciate. When combined with the concept of simplicity, wood creates a product that can be built, relocated, combined, rebuilt elsewhere, and recombined again.

Our personal approach

We will tailor your project to your needs. We will assist you in selecting and appropriately combining modules and recommend ways to obtain support through grants and financing. Throughout the entire process, from consultation to implementation, will be guided by a single team member who will be your partner throughout the construction process.

We enjoy combinations

The modules can be freely combined, allowing you to achieve a unique building layout. The design of our product enables the stacking of floors. ModuleWorks can be dismantled at any time and relocated to a different site, expanded with additional spaces, or used as an extension on existing buildings.

Technology and development

ModuleWorks are simple and have a minimalist design, making them suitable for any environment. We actively collaborate with university research teams at CTU Prague, young innovators, and renowned experts who contribute to the development and fulfillment of the latest construction requirements, such as DNSH principles and SB Tools certification.

Production in the Hall

The production of ModuleWorks takes place in a closed hall. During assembly, continuous quality control is carried out. Unlike brick constructions, the product is not exposed to negative environmental influences. The installation of the building itself does not require the setup of a construction site, ensuring that the assembly process has no negative impact on the surrounding area of the construction site.

Fire Resistance

We have subjected our ModuleWorks to fire testing to ensure your safety and guarantee the required fire resistance. Fire protection is guaranteed at least REI 30 from the interior side.

0

dm3

Insulating PUR foams

0

m2

OSB boards

0

pcs

Stainless steel boreholes

0

bm

Larch cladding boards

Modules

Who are you?

01

Bussiness

02

Institutions

03

People

Energy savings

We utilize our proprietary technology of lightweight, prefabricated frame construction with integrated PUR foam insulation

Modularity

The modularity of our timber buildings offers unparalleled flexibility and adaptability to your needs.

Wood

Dried spruce wood is used as the primary building material.

Gallery

Projects

Our modules are already WORKING AND LIVING, fulfilling their purpose.

Query

Contact us

Do you need a

tailor-made solution?

ModuleWorks is a unique project by IHOMA Solutions Ltd., a construction company specializing in innovative building solutions. We can create everything from clinics to apartments and family houses, offering both customized and standard designs.

Our expertise lies in the PURLIVE Structural Insulated Panel (SIP) building system, which is certified by the Woodworking Institute. This system offers versatility and is suitable for a wide range of applications, including individual homes, commercial projects, and amenity buildings. At ModuleWorks, our mission is to deliver simple, original, and effective solutions tailored to your needs.